Volume 5, Issue 3 (july 2021)

AOH 2021, 5(3): 1059-1067 |

Back to browse issues page

Download citation:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

Shaban I, Farshad A, Yarahmadi R, Mansourian M, Kharghani Moghadam S M, Abedi K et al . Exploring the Viewpoint of Oil Industry Employees about Factors Affecting the Success of Standard Operating Procedures. AOH 2021; 5 (3) :1059-1067

URL: http://aoh.ssu.ac.ir/article-1-263-en.html

URL: http://aoh.ssu.ac.ir/article-1-263-en.html

Iman Shaban1

, Aliasghar Farshad2

, Aliasghar Farshad2

, Rasoul Yarahmadi3

, Rasoul Yarahmadi3

, Morteza Mansourian4

, Morteza Mansourian4

, Seyedeh Melika Kharghani Moghadam4

, Seyedeh Melika Kharghani Moghadam4

, Kamaladdin Abedi5

, Kamaladdin Abedi5

, Hossein Ebrahimi *

, Hossein Ebrahimi *

6

6

, Aliasghar Farshad2

, Aliasghar Farshad2

, Rasoul Yarahmadi3

, Rasoul Yarahmadi3

, Morteza Mansourian4

, Morteza Mansourian4

, Seyedeh Melika Kharghani Moghadam4

, Seyedeh Melika Kharghani Moghadam4

, Kamaladdin Abedi5

, Kamaladdin Abedi5

, Hossein Ebrahimi *

, Hossein Ebrahimi *

6

6

1- Department of occupational health, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

2- Occupational Health Research Center (OHRC), School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

3- Air pollution research center, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

4- Department of o health education and health promotion, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

5- Department of occupational health engineering, faculty of health, Kurdistan University of Medical Sciences, Sanandaj, Iran

6- Air pollution research center, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran , hossein.ebrahimi@yahoo.com

2- Occupational Health Research Center (OHRC), School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

3- Air pollution research center, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

4- Department of o health education and health promotion, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran

5- Department of occupational health engineering, faculty of health, Kurdistan University of Medical Sciences, Sanandaj, Iran

6- Air pollution research center, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran , hossein.ebrahimi@yahoo.com

Full-Text [PDF 3138 kb]

(234 Downloads)

| Abstract (HTML) (716 Views)

rocess industries are called industries in which materials are converted into interstitial or final products by means of physical chemical processes or other methods. 1 In these industries, production, storage, transportation, application, and disposal of chemicals are potentially dangerous, 2 also they are highly prone to catastrophic events. Since the beginning of the 20th century, numerous accidents have occurred in these industries. 3 Such accidents in process industries with the sensitivity of the general public over the past years have caused a lot of attention to the safety and prevention of accidents. Therefore, many measures have been taken to improve the safety of these industries. 4, 5 The establishment and application of a safety management system are one of the measures taken in this field. According to the OSHA forecast, 6-10 years after implementing process safety management (PSM), accidents decreased by about 80%, and it prevented approximately 264 deaths and 1,534 cases of injuries or diseases annually. 6 Over the past years, PSM performance has been evaluated by different researchers. In the study conducted by Bridges in 25 large US companies, although the cost of PSM implementation was estimated, most companies gained higher benefits due to PSM implementation. Generally, most of the companies agreed with the establishment of PSM. 7 In another research, seven years after introducing PSM in the South Korean chemical industry, 62% of deaths, 58% of injuries, and 82% of quasi-accidents were reduced. Moreover, the quality and productivity index improved. 8

One of the safety management components is standard operating procedures (SOPs); SOPs are a set of written procedures, which document the method of safe operation of cases involving in risky materials or risky operations. Very general or poorly written SOPs have limited application. Therefore, SOPs must be written in sufficient detail and accuracy to ensure that they can be used with minimal likelihood of misunderstanding or error. However, if the user is not properly trained or certain human and cultural factors are not considered, the written SOPs will not be effective. Sometimes workers in complex environments do not pay attention to procedures; furthermore, in some of these environments, they use very old procedures. 9 The workers distrust of procedures; since they are outdated or incorrect. 10 The lack of using the instructions is due the overload of information; also, researchers reported that the

high work and experience of workers affect the method of working. 11 Considering the importance of SOPs and the existence of different factors affecting their success except for process safety management, this study was conducted to investigate the viewpoints of the employees of an oil industry about the factors affecting the success of SOPs.

Methods

Ethical confirmation

Ethical code, IR.IUMS.REC.1398.1179, was received from the Research Ethics Committee of Iran University of Medical Sciences for this study and informed consent form was obtained from the participants.

Target community

This qualitative study was conducted in 2020 in Tehran Oil Refining Company. Tehran Refinery is an Iranian oil refining company with a refining capacity of 235,000 barrels per day. This refinery was established in 1968 and currently consists of two refineries, south and north, whose facilities are located in the south of Tehran. This company has 2469 employees who work in different units. The sampling of the interviewed workers was done based on goal oriented by using the snowball method. 12In this method, the researcher favors viewpoints, comments, and attitudes of special persons to be included in the obtained results. The inclusion criteria were 1) involving in the executive standards and 2) having satisfaction with the interview; thirty interviews were done, 26 of which were appropriate and completed for careful analysis.

Data collection tools

In this study, the semi-structured

interview questionnaire, voice recorder, and

MAX-QDA software were used to collect and

analyze the data.

Semi-structured interview questionnaire: in order to ensure that the interviewees were asked about the fundamental questions regarding the factors affecting the applicability of the SOPs , a questionnaire containing basic questions was prepared. The questionnaire was designed based on a review of the texts and objectives of the study. The questions of the questionnaire included:

1- What is your understanding of SOPs?

2- What are the benefits of using SOPs ?

3- What factors or conditions make the SOPs applicable?

4- What factors or conditions prevent the applicability of the SOPs?

5- What is your motivation for using the SOPs?

6- Describe the advantages and disadvantages of existing SOPs.

7- Explain your experience about using SOPs?

8- Are you satisfied with the results of using the SOPs?

9- What are the consequences of using SOPs for you?

10- Have you achieved the expected consequences of using SOPs?

11- Do you recommend using SOPs to your

friends?

Voice recorder: in this study, Tesco TR 908 audio recorder was used to record the interviews.

MAX-QDA software: this software was designed for qualitative, quantitative, and mixed methods research. This software is also used for qualitative data analysis and theorizing. Regarding the capabilities of this software, we can mention the ability to import various documents, such as text documents, pdf, audio, video, YouTube comments, spreadsheet documents, tables and various items, as well as coding and analysis of the data.

Methodology

The semi-structured face to face interviews were used to collect the data. The interviews were continued by the researcher until they were saturated. The reason for collecting the data by only one person was to minimize the level of error in data collection and to conduct all the interviews by a person who is well informed about the subject. The average duration of each interview lasted 40-60 minutes. The interview location was determined by the interviewees themselves when most interviews happened at their workplace. At first, the study purpose was completely explained for the interviewees, and they were assured that all the information obtained would be confidential, as well as the results of the study would be reported in general. Therefore, after filling out the ethical consent form (appendix 1), the researcher started the interview. The interviews were continued until the saturation.

The content analysis method was used to analyze the participants' responses; immediately after each interview, the data were entered into MAX-QDA software, and the themes were extracted. Finally, the main topics of the study were obtained by reviewing the codes and themes.

To confirm the main themes, the data extracted from the interviews and recorded materials were separately reviewed by two research team members to analyze the information and achieve a consensus on the main themes of the research. Besides, all notes and interpretations related to them were returned to the participants to be considered (member check).

Results

In total, 26 employees of the Oil Refining Company with mean age of 32.19±6.06 years were interviewed. The results of work experience and accident experience for the interviewed employees are listed in Tables 1 and 2.

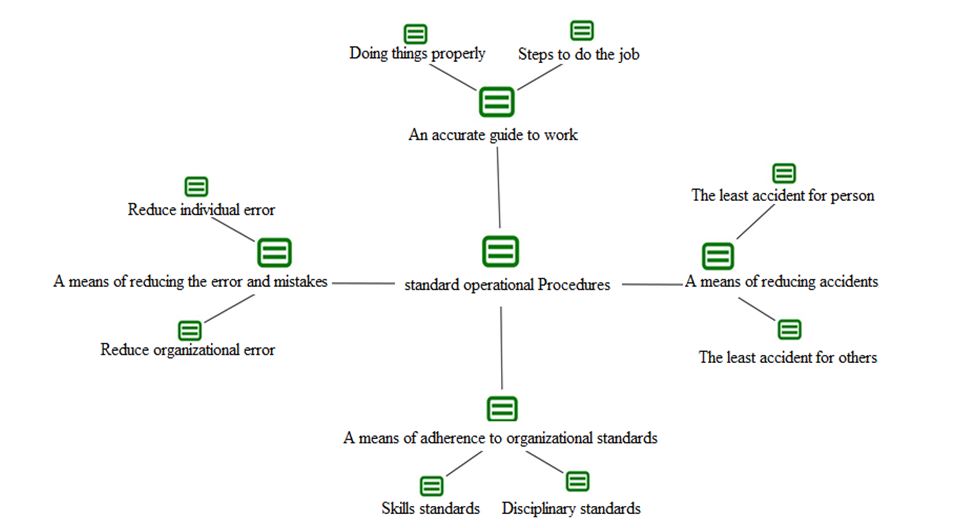

There was an almost clear understanding of the SOPs in all the interviews. The most prepared respondents, in terms of information about the SOPs, responded almost identically to their SOP, namely, "the steps necessary to do a specific task with the details of that work or that department so that it is always done in the same right and the same way, regardless of the individual differences of the employees". Other respondents had almost defined close proximity to these definitions. Figure 1 reveals the perception of the staff of standard operating procedures.

Figure 1 reveals the perception of the employees of standard producers, including an accurate guide to work, a means of reducing accidents, observing organizational, and factor standards for reducing individual and organizational errors.

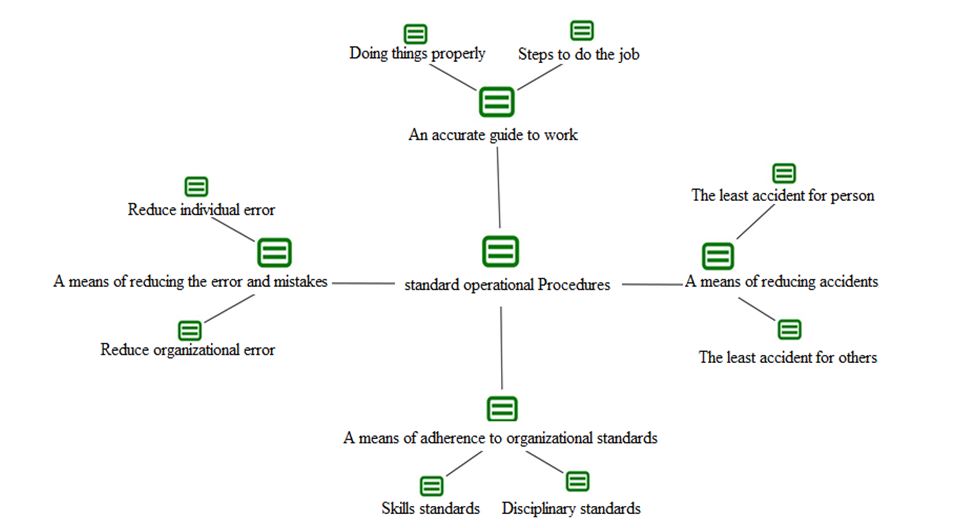

Each interviewee raised on expertise, experiences, organizational posts, and other factors, presented their views for successfully implementing SOPs in the organization, including organizational, individual, and environmental factors. Figure 2 shows the employees' viewpoints about organizational, individual, and environmental factors affecting the applicability of standard executive instructions.

Discussion

The main objective of this study was to explain the viewpoints of the oil industry employees about the applicability of SOPs. The level of applicability is affected by the acceptance rate. Acceptance is one of the most inclusive indicators in the field of social sciences, behavioral sciences, and sciences related to

planning and management. In this study, acceptance was considered in the form of behavioral assessment of a person or the formation of behavioral action related to standard operational procedures. In most different studies, no single definition of this index has been observed. The acceptance of one of comprehensive indicators in the area of social, behavioral sciences is related to planning and management. 13 This definition of the index is usually practically related to future implementation issues and theoretically similar to the willingness to accept words. The results of this study showed that most of the employees had a positive attitude towards the procedures, which were seen as a means of better-performing things and reducing the rate of accidents.

Table 1. Distribution of interviewees based on work experience

Table 2. Distribution of interviewees based on accident experience

Figure 1. Employees' views about perceptions and motivations for using SOPs

Figure 2. Employees' views about success factors of SOPs

Full-Text: (430 Views)

Exploring the Viewpoint of Oil Industry Employees about Factors Affecting the Success of Standard Operating Procedures

Iman Shaban 1, Ali asghar Farshad 2, Rasoul Yarahmadi 3, Morteza Mansourian 4, Seyedeh Melika Kharghani Moghadam 4, Kamaladdin Abedi 5, Hossein Ebrahimi 3*

1- Department of occupational health, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 2 Occupational Health Research Center (OHRC), School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 3 Air pollution research center, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 4 Department of o health education and health promotion, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 5 Department of occupational health engineering, faculty of health, Kurdistan University of Medical Sciences, Sanandaj, Iran• *Corresponding author: Hossein Ebrahimi, Email: hossein.ebrahimi@yahoo.com

Abstract

Background: Different factors affect the success of standard operational procedures (SOPs). This study was conducted to explore the viewpoints of employees of Tehran Oil Refining Company about factors affecting the usability of SOPs. Methods: This qualitative study was a conventional content analysis research conducted on the oil refining company employers 2020, using the semi-structured interviews. The data were analyzed by content analysis method using MAXQDA software. Results: The results showed that the employees had a positive perception toward the standard operating procedures and most of them used these procedures to improve work performance and reduce accidents. Also, from the viewpoint of the employees, organizational factors (desirable organizational culture, continuous supervision and evaluation and assurance of accurate implementation of instructions, and continuous personnel training), individual factors (positive perception of the personnel about the organization goals, rules obedience of the personnel, positive experiences of personnel from the implementation of instructions in the past), and environmental factors (environmental dynamics and their related SOP dynamics, desirable but formal relationships of managers and supervisors with personnel as well as optimal and standard work schedule) had a positive effect on the applicability of these procedures. Conclusion: The findings of this study showed that the employees, consider standard operating procedures of organizational, individual, and environmental factors effective in using standard operating instructions. Therefore, to increase the applicability of these procedures, the employees should consider their opinions.

Keywords: Chemical industry; Standard operating procedures; Qualitative study; Safety

Introduction

Iman Shaban 1, Ali asghar Farshad 2, Rasoul Yarahmadi 3, Morteza Mansourian 4, Seyedeh Melika Kharghani Moghadam 4, Kamaladdin Abedi 5, Hossein Ebrahimi 3*

1- Department of occupational health, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 2 Occupational Health Research Center (OHRC), School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 3 Air pollution research center, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 4 Department of o health education and health promotion, School of health, Iran University of Medical Sciences (IUMS), Tehran, Iran• 5 Department of occupational health engineering, faculty of health, Kurdistan University of Medical Sciences, Sanandaj, Iran• *Corresponding author: Hossein Ebrahimi, Email: hossein.ebrahimi@yahoo.com

Abstract

Background: Different factors affect the success of standard operational procedures (SOPs). This study was conducted to explore the viewpoints of employees of Tehran Oil Refining Company about factors affecting the usability of SOPs. Methods: This qualitative study was a conventional content analysis research conducted on the oil refining company employers 2020, using the semi-structured interviews. The data were analyzed by content analysis method using MAXQDA software. Results: The results showed that the employees had a positive perception toward the standard operating procedures and most of them used these procedures to improve work performance and reduce accidents. Also, from the viewpoint of the employees, organizational factors (desirable organizational culture, continuous supervision and evaluation and assurance of accurate implementation of instructions, and continuous personnel training), individual factors (positive perception of the personnel about the organization goals, rules obedience of the personnel, positive experiences of personnel from the implementation of instructions in the past), and environmental factors (environmental dynamics and their related SOP dynamics, desirable but formal relationships of managers and supervisors with personnel as well as optimal and standard work schedule) had a positive effect on the applicability of these procedures. Conclusion: The findings of this study showed that the employees, consider standard operating procedures of organizational, individual, and environmental factors effective in using standard operating instructions. Therefore, to increase the applicability of these procedures, the employees should consider their opinions.

Keywords: Chemical industry; Standard operating procedures; Qualitative study; Safety

Introduction

| P |

One of the safety management components is standard operating procedures (SOPs); SOPs are a set of written procedures, which document the method of safe operation of cases involving in risky materials or risky operations. Very general or poorly written SOPs have limited application. Therefore, SOPs must be written in sufficient detail and accuracy to ensure that they can be used with minimal likelihood of misunderstanding or error. However, if the user is not properly trained or certain human and cultural factors are not considered, the written SOPs will not be effective. Sometimes workers in complex environments do not pay attention to procedures; furthermore, in some of these environments, they use very old procedures. 9 The workers distrust of procedures; since they are outdated or incorrect. 10 The lack of using the instructions is due the overload of information; also, researchers reported that the

high work and experience of workers affect the method of working. 11 Considering the importance of SOPs and the existence of different factors affecting their success except for process safety management, this study was conducted to investigate the viewpoints of the employees of an oil industry about the factors affecting the success of SOPs.

Methods

Ethical confirmation

Ethical code, IR.IUMS.REC.1398.1179, was received from the Research Ethics Committee of Iran University of Medical Sciences for this study and informed consent form was obtained from the participants.

Target community

This qualitative study was conducted in 2020 in Tehran Oil Refining Company. Tehran Refinery is an Iranian oil refining company with a refining capacity of 235,000 barrels per day. This refinery was established in 1968 and currently consists of two refineries, south and north, whose facilities are located in the south of Tehran. This company has 2469 employees who work in different units. The sampling of the interviewed workers was done based on goal oriented by using the snowball method. 12In this method, the researcher favors viewpoints, comments, and attitudes of special persons to be included in the obtained results. The inclusion criteria were 1) involving in the executive standards and 2) having satisfaction with the interview; thirty interviews were done, 26 of which were appropriate and completed for careful analysis.

Data collection tools

In this study, the semi-structured

interview questionnaire, voice recorder, and

MAX-QDA software were used to collect and

analyze the data.

Semi-structured interview questionnaire: in order to ensure that the interviewees were asked about the fundamental questions regarding the factors affecting the applicability of the SOPs , a questionnaire containing basic questions was prepared. The questionnaire was designed based on a review of the texts and objectives of the study. The questions of the questionnaire included:

1- What is your understanding of SOPs?

2- What are the benefits of using SOPs ?

3- What factors or conditions make the SOPs applicable?

4- What factors or conditions prevent the applicability of the SOPs?

5- What is your motivation for using the SOPs?

6- Describe the advantages and disadvantages of existing SOPs.

7- Explain your experience about using SOPs?

8- Are you satisfied with the results of using the SOPs?

9- What are the consequences of using SOPs for you?

10- Have you achieved the expected consequences of using SOPs?

11- Do you recommend using SOPs to your

friends?

Voice recorder: in this study, Tesco TR 908 audio recorder was used to record the interviews.

MAX-QDA software: this software was designed for qualitative, quantitative, and mixed methods research. This software is also used for qualitative data analysis and theorizing. Regarding the capabilities of this software, we can mention the ability to import various documents, such as text documents, pdf, audio, video, YouTube comments, spreadsheet documents, tables and various items, as well as coding and analysis of the data.

Methodology

The semi-structured face to face interviews were used to collect the data. The interviews were continued by the researcher until they were saturated. The reason for collecting the data by only one person was to minimize the level of error in data collection and to conduct all the interviews by a person who is well informed about the subject. The average duration of each interview lasted 40-60 minutes. The interview location was determined by the interviewees themselves when most interviews happened at their workplace. At first, the study purpose was completely explained for the interviewees, and they were assured that all the information obtained would be confidential, as well as the results of the study would be reported in general. Therefore, after filling out the ethical consent form (appendix 1), the researcher started the interview. The interviews were continued until the saturation.

The content analysis method was used to analyze the participants' responses; immediately after each interview, the data were entered into MAX-QDA software, and the themes were extracted. Finally, the main topics of the study were obtained by reviewing the codes and themes.

To confirm the main themes, the data extracted from the interviews and recorded materials were separately reviewed by two research team members to analyze the information and achieve a consensus on the main themes of the research. Besides, all notes and interpretations related to them were returned to the participants to be considered (member check).

Results

In total, 26 employees of the Oil Refining Company with mean age of 32.19±6.06 years were interviewed. The results of work experience and accident experience for the interviewed employees are listed in Tables 1 and 2.

There was an almost clear understanding of the SOPs in all the interviews. The most prepared respondents, in terms of information about the SOPs, responded almost identically to their SOP, namely, "the steps necessary to do a specific task with the details of that work or that department so that it is always done in the same right and the same way, regardless of the individual differences of the employees". Other respondents had almost defined close proximity to these definitions. Figure 1 reveals the perception of the staff of standard operating procedures.

Figure 1 reveals the perception of the employees of standard producers, including an accurate guide to work, a means of reducing accidents, observing organizational, and factor standards for reducing individual and organizational errors.

Each interviewee raised on expertise, experiences, organizational posts, and other factors, presented their views for successfully implementing SOPs in the organization, including organizational, individual, and environmental factors. Figure 2 shows the employees' viewpoints about organizational, individual, and environmental factors affecting the applicability of standard executive instructions.

Discussion

The main objective of this study was to explain the viewpoints of the oil industry employees about the applicability of SOPs. The level of applicability is affected by the acceptance rate. Acceptance is one of the most inclusive indicators in the field of social sciences, behavioral sciences, and sciences related to

planning and management. In this study, acceptance was considered in the form of behavioral assessment of a person or the formation of behavioral action related to standard operational procedures. In most different studies, no single definition of this index has been observed. The acceptance of one of comprehensive indicators in the area of social, behavioral sciences is related to planning and management. 13 This definition of the index is usually practically related to future implementation issues and theoretically similar to the willingness to accept words. The results of this study showed that most of the employees had a positive attitude towards the procedures, which were seen as a means of better-performing things and reducing the rate of accidents.

Table 1. Distribution of interviewees based on work experience

| Work experience (Year) | Frequency | Percentage |

| 1-10 | 7 | 26.9 |

| 11-20 | 11 | 42.3 |

| > 20 | 8 | 30.8 |

| Accident experience | Frequency | Percentage |

| For the interviewees | 4 | 15.4 |

| For coworkers | 5 | 19.2 |

| Total | 9 | 34.6 |

Figure 1. Employees' views about perceptions and motivations for using SOPs

Figure 2. Employees' views about success factors of SOPs

From the employees' point of view, organizational factors affecting the application of standard operating procedures included desirable organizational culture, continuous supervision and evaluation, and organizational assurance of accurate implementation of the instructions and continuous personnel training.

The world has seen the revival of researchers' attention to the nature and impact of organizational culture on the organization and modern work over the past 30 years. 14 Organizational culture is defined as a set of common beliefs and values affecting members of the organization behavior and thought and can be a starting point for movement and dynamics or obstacles to progress. Organizational culture is one of the most basic areas of change in the organization. Since new programs pay more attention to fundamental organizational development, these programs aim to change and transform organizational culture as the basis of evolution. 15 Therefore, to apply the standard operating procedures, organizational culture governing the industry should be changed. Different components have been defined for organizational culture. Cameron and Quinn consider organizational culture as components, such as management model, strategic programs, organizational climate, reward system, leadership, and fundamental values of the organization that these components should be studied and changed for organizational change. 16 For organizational culture, Robins determined nine components, including creativity and innovation, risk-taking, considering details, outcome and organization members, the effect of decisions on employees, attention to the team, ambition, and intimacy. 17 Therefore, desirable organizational culture by creating a suitable safety culture in the industry, accurate implementation of the instructions, and paying attention to the details of the application instructions can increase the applicability of the instructions.

Continuous monitoring and evaluation and assurance of the organization from the accurate and correct implementation of the instructions were another effective organizational factor in applying standard executive instructions from the staff's point of view. To date, various approaches have been used to improve the status of HSE management system in organizations, each of which has its own results. Auditing is of special importance because, in fact, by performing a proper audit, the risks and non-compliance in all cases in the HSE management system are identified. The result is management intervention in eliminating defects and achieving compliance according to standards and regulations. Applying the correct components in the audit method is very important because it examines all the pros in a comprehensive and complete way 18. The purpose of the review is to determine whether the predetermined standards have been fulfilled, and otherwise, the basis for improvement is determined. All the measures are valuable in identifying strengths, identifying the imprints, and helping to set priorities for corrective measures. 18, 19 Thus, auditing or continuous evaluation of standard executive instructions can affect the applicability of procedures by identifying the defects and eliminating these defects.

Achieving safety in an acceptable level in different industrial activities and attaining a developed safety culture require fundamental measures that are the most important requirements to create the necessary conditions for improving the level of employees' awareness in workplace. The role of education as an axis of progress and development in different fields is of great importance in reducing accidents. 20 Developing standard executive instructions without training the purpose of these procedures and how to use these instructions certainly leads to the lack of applying these procedures. In order to these procedures, it is essential to have a proper understanding of the instructions and use them. Therefore, education is one of the organizational factors affecting the application of these procedures in the industry in terms of the staff's viewpoint.

From the viewpoint of the employees, the individual factors affecting the applicability of standard executive instructions include the positive perception of personnel from the SOPs and the goals of the organization, the law obedience of personnel, and the positive experiences of personnel from the implementation of the instructions in the past times.

Safety culture is the product of individual and group values, tendencies, efficiency, and behavioral model that determines the level of commitment, empowerment, and efficiency of an organization's health and safety program; 21 having a desirable safety culture is the desire of all organizations and even human societies. Safety experts have found that 80-90% of work-related accidents occur due to insecurity behaviors and, even though many technical efforts have been made and rules have been imposed, industries pay high costs for accident; therefore, safety culture as a special approach in safety management has been considered more day by day. 22 If all employees recognize safety as a key value in the organization, the safety culture will be clear. 23 Safety culture is a complex structure in organization that includes attitudes, values, and safety behavior of members of the organization, most of which are potentially changeable, associated with actual incident-taking behavior. 24, 25 Creating a safety culture by changing people's motivations regardless of job and organizational aspects or changing people's behavior regardless of their motivations and organizational systems and changing systems regardless of the interaction of psychological behavioral and organizational factors will be doomed to failure. 26, 27 After several studies, social psychologists have concluded that individuals' attitudes are the most important factors for predicting their behaviors. Studies on safety attitudes have shown that individuals with negative safety attitudes are risky for themselves and others. For example, in driving accidents, negative safety attitudes often lead to unsafe actions and ultimately accidents. 27 Hence, employees' positive attitude toward standard operating procedures can affect employees' behavior and use these procedures. On the other hand, the negative attitude of employees reduces usability.

From the staff's point of view, employees' law obedience was another individual factor affecting the applicability of standard operating procedures. Different parameters can affect individuals' safety performance. One of the most important factors is the commitment to safety. When commitment to safety is mentioned, it is usually emphasized on management commitment to safety. Management commitment to safety is very important to the point where no safety program will be concluded without a real management commitment. 28 Although the role of management commitment to safety in improving employee safety performance is well known, there are fewer studies on individuals and staff commitment to safety. Although strong safety starts with the organization, real safety is the collective result of industry employees' behavior. Therefore, it can be proposed that individual commitment to safety can significantly affect the organization's safety outputs. Past studies have pointed to the role of individual commitment to safety. For example, individual commitment to safety is mentioned as one of dimensions of the safety climate. 28 Individual commitment to safety could improve individual safety performance. 29 Thus, commitment or the same law of the employees to safety and, consequently, standard operating procedures can affect these procedures.

Positive experiences of personnel from the implementation of the procedures in the past were another factor affecting the applicability of executive instructions from the employees' viewpoint. When one has already experienced the results of the implementation of this instruction, and is satisfied with it and has gained positive experience, it is preventing the repetition of this positive experience. Moreover, when there is a positive experience of the execution of these instructions among colleagues in the organization, they are eager to implement these instructions correctly in the organization and try to coordinate others with themselves in this regard, which can help to implement the procedures successfully. 9

From the employees' viewpoint, environmental factors affecting the applicability of standard operating procedures, including environmental dynamics and their related SOP dynamics, desirable but law-based relationships of managers and supervisors with personnel, and desirable hours and shifts. Each environment has specific expectations from the organization and provides opportunities and situations. By collecting information about environmental events and analyzing and evaluating them, the organization learns about the existence of requests and situations and designs or adjusts its strategy by using this information to achieve its goal. Due to the dynamics of the environment, if the SOP is in sync with these environmental events and designs its instructions according to these events, the organization's willingness to implement these instructions correctly increases and the organization takes effective steps to implement these procedures successfully to adapt to the new conditions. 9

Desirable but law-based relationships between managers and supervisors with personnel were another factor influencing the application of standard operating procedures from the staff's perspective. One reason for not observing safety and health laws and regulations is its low priority for jobs and organizations. If an organization or job does not have a complete and mature safety culture, other goals, such as production will be of higher value. To change that, the perceived value of safety must rise. 30 One way to increase safety perception is workers' participation in the risk assessment process. The Alberta Municipal Health and Safety Association (AMHSA) reported in a study that many agencies directly contribute workers to the risk assessment process. This partnership included the presence of the workers in group meetings and discussions. This type of workers' participation increases safety perception and is a major component in reducing accidents. Without proper interpersonal communication, the person suffers from isolation and depression in workplace, affecting his/her job satisfaction. Job satisfaction is an emotional orientation that a person has concerning his job, and employees with job satisfaction are in good physical and mental ability. 31, 32 Without good interpersonal relationships, we cannot expect to create emotional orientation towards job and job satisfaction. Therefore, desirable interpersonal relationships in workplace by creating emotional orientation towards a job motivate the person to perform better tasks. Better performing tasks requires using standard executive instructions. Hence, desirable interpersonal relationships eventually lead to an increase in the applicability of standard operating procedures.

There is a shift work phenomenon in many industries and factories, such as steel, oil, petrochemical, power plants, and generally any industry in which heavy economic investment has been made. 33 Different studies have shown that performance in night shifts decreases by 5-10%. Night shifts decrease by 30% when accompanied by sleep deprivation the following day. 34 In addition to a change in people's working performance following insomnia, its physical and psychological effects are well known. One of these effects is the effect on the cognitive functioning of individuals. Memory, accuracy, attention, and reaction time are important cognitive variables in information processing that change in sleep deprivation. 35 Since using standard executive instructions requires individuals' cognitive functioning, therefore, changing the cognitive functioning of individuals at different hours of the day can affect the applicability of standard operating procedures.

Limitations

The limitations of this study included the small study interval, a large number of confounding variables, and the limit of generalizing the results to other organizations.

Conclusion

The results of this study indicated that the employees understood and considered the standard operating procedures positive lying and often considered the use of these procedures for better performance and reducing accidents. Also, from the viewpoint of employees, organizational factors (desirable organizational culture, continuous supervision and evaluation and assurance of accurate implementation of instructions, and continuous personnel training), individual factors (positive perception of personnel from the organization's goals, law obedience of personnel, and positive experiences of personnel from the implementation of instructions in the past), and environmental factors (environmental dynamics and their related SOP dynamics, desirable but law-based relationships of managers and supervisors with personnel as well as optimal and standard hours and shifts ) had a positive effect on the applicability of these procedures.

Conflicts of Interest

The authors declare that there is no conflict of interest.

Author contributions: All authors contributed equally to the study.

Acknowledgements

Authors would like to thank the employees of Tehran Oil Refinery who participated in this study.

References

The world has seen the revival of researchers' attention to the nature and impact of organizational culture on the organization and modern work over the past 30 years. 14 Organizational culture is defined as a set of common beliefs and values affecting members of the organization behavior and thought and can be a starting point for movement and dynamics or obstacles to progress. Organizational culture is one of the most basic areas of change in the organization. Since new programs pay more attention to fundamental organizational development, these programs aim to change and transform organizational culture as the basis of evolution. 15 Therefore, to apply the standard operating procedures, organizational culture governing the industry should be changed. Different components have been defined for organizational culture. Cameron and Quinn consider organizational culture as components, such as management model, strategic programs, organizational climate, reward system, leadership, and fundamental values of the organization that these components should be studied and changed for organizational change. 16 For organizational culture, Robins determined nine components, including creativity and innovation, risk-taking, considering details, outcome and organization members, the effect of decisions on employees, attention to the team, ambition, and intimacy. 17 Therefore, desirable organizational culture by creating a suitable safety culture in the industry, accurate implementation of the instructions, and paying attention to the details of the application instructions can increase the applicability of the instructions.

Continuous monitoring and evaluation and assurance of the organization from the accurate and correct implementation of the instructions were another effective organizational factor in applying standard executive instructions from the staff's point of view. To date, various approaches have been used to improve the status of HSE management system in organizations, each of which has its own results. Auditing is of special importance because, in fact, by performing a proper audit, the risks and non-compliance in all cases in the HSE management system are identified. The result is management intervention in eliminating defects and achieving compliance according to standards and regulations. Applying the correct components in the audit method is very important because it examines all the pros in a comprehensive and complete way 18. The purpose of the review is to determine whether the predetermined standards have been fulfilled, and otherwise, the basis for improvement is determined. All the measures are valuable in identifying strengths, identifying the imprints, and helping to set priorities for corrective measures. 18, 19 Thus, auditing or continuous evaluation of standard executive instructions can affect the applicability of procedures by identifying the defects and eliminating these defects.

Achieving safety in an acceptable level in different industrial activities and attaining a developed safety culture require fundamental measures that are the most important requirements to create the necessary conditions for improving the level of employees' awareness in workplace. The role of education as an axis of progress and development in different fields is of great importance in reducing accidents. 20 Developing standard executive instructions without training the purpose of these procedures and how to use these instructions certainly leads to the lack of applying these procedures. In order to these procedures, it is essential to have a proper understanding of the instructions and use them. Therefore, education is one of the organizational factors affecting the application of these procedures in the industry in terms of the staff's viewpoint.

From the viewpoint of the employees, the individual factors affecting the applicability of standard executive instructions include the positive perception of personnel from the SOPs and the goals of the organization, the law obedience of personnel, and the positive experiences of personnel from the implementation of the instructions in the past times.

Safety culture is the product of individual and group values, tendencies, efficiency, and behavioral model that determines the level of commitment, empowerment, and efficiency of an organization's health and safety program; 21 having a desirable safety culture is the desire of all organizations and even human societies. Safety experts have found that 80-90% of work-related accidents occur due to insecurity behaviors and, even though many technical efforts have been made and rules have been imposed, industries pay high costs for accident; therefore, safety culture as a special approach in safety management has been considered more day by day. 22 If all employees recognize safety as a key value in the organization, the safety culture will be clear. 23 Safety culture is a complex structure in organization that includes attitudes, values, and safety behavior of members of the organization, most of which are potentially changeable, associated with actual incident-taking behavior. 24, 25 Creating a safety culture by changing people's motivations regardless of job and organizational aspects or changing people's behavior regardless of their motivations and organizational systems and changing systems regardless of the interaction of psychological behavioral and organizational factors will be doomed to failure. 26, 27 After several studies, social psychologists have concluded that individuals' attitudes are the most important factors for predicting their behaviors. Studies on safety attitudes have shown that individuals with negative safety attitudes are risky for themselves and others. For example, in driving accidents, negative safety attitudes often lead to unsafe actions and ultimately accidents. 27 Hence, employees' positive attitude toward standard operating procedures can affect employees' behavior and use these procedures. On the other hand, the negative attitude of employees reduces usability.

From the staff's point of view, employees' law obedience was another individual factor affecting the applicability of standard operating procedures. Different parameters can affect individuals' safety performance. One of the most important factors is the commitment to safety. When commitment to safety is mentioned, it is usually emphasized on management commitment to safety. Management commitment to safety is very important to the point where no safety program will be concluded without a real management commitment. 28 Although the role of management commitment to safety in improving employee safety performance is well known, there are fewer studies on individuals and staff commitment to safety. Although strong safety starts with the organization, real safety is the collective result of industry employees' behavior. Therefore, it can be proposed that individual commitment to safety can significantly affect the organization's safety outputs. Past studies have pointed to the role of individual commitment to safety. For example, individual commitment to safety is mentioned as one of dimensions of the safety climate. 28 Individual commitment to safety could improve individual safety performance. 29 Thus, commitment or the same law of the employees to safety and, consequently, standard operating procedures can affect these procedures.

Positive experiences of personnel from the implementation of the procedures in the past were another factor affecting the applicability of executive instructions from the employees' viewpoint. When one has already experienced the results of the implementation of this instruction, and is satisfied with it and has gained positive experience, it is preventing the repetition of this positive experience. Moreover, when there is a positive experience of the execution of these instructions among colleagues in the organization, they are eager to implement these instructions correctly in the organization and try to coordinate others with themselves in this regard, which can help to implement the procedures successfully. 9

From the employees' viewpoint, environmental factors affecting the applicability of standard operating procedures, including environmental dynamics and their related SOP dynamics, desirable but law-based relationships of managers and supervisors with personnel, and desirable hours and shifts. Each environment has specific expectations from the organization and provides opportunities and situations. By collecting information about environmental events and analyzing and evaluating them, the organization learns about the existence of requests and situations and designs or adjusts its strategy by using this information to achieve its goal. Due to the dynamics of the environment, if the SOP is in sync with these environmental events and designs its instructions according to these events, the organization's willingness to implement these instructions correctly increases and the organization takes effective steps to implement these procedures successfully to adapt to the new conditions. 9

Desirable but law-based relationships between managers and supervisors with personnel were another factor influencing the application of standard operating procedures from the staff's perspective. One reason for not observing safety and health laws and regulations is its low priority for jobs and organizations. If an organization or job does not have a complete and mature safety culture, other goals, such as production will be of higher value. To change that, the perceived value of safety must rise. 30 One way to increase safety perception is workers' participation in the risk assessment process. The Alberta Municipal Health and Safety Association (AMHSA) reported in a study that many agencies directly contribute workers to the risk assessment process. This partnership included the presence of the workers in group meetings and discussions. This type of workers' participation increases safety perception and is a major component in reducing accidents. Without proper interpersonal communication, the person suffers from isolation and depression in workplace, affecting his/her job satisfaction. Job satisfaction is an emotional orientation that a person has concerning his job, and employees with job satisfaction are in good physical and mental ability. 31, 32 Without good interpersonal relationships, we cannot expect to create emotional orientation towards job and job satisfaction. Therefore, desirable interpersonal relationships in workplace by creating emotional orientation towards a job motivate the person to perform better tasks. Better performing tasks requires using standard executive instructions. Hence, desirable interpersonal relationships eventually lead to an increase in the applicability of standard operating procedures.

There is a shift work phenomenon in many industries and factories, such as steel, oil, petrochemical, power plants, and generally any industry in which heavy economic investment has been made. 33 Different studies have shown that performance in night shifts decreases by 5-10%. Night shifts decrease by 30% when accompanied by sleep deprivation the following day. 34 In addition to a change in people's working performance following insomnia, its physical and psychological effects are well known. One of these effects is the effect on the cognitive functioning of individuals. Memory, accuracy, attention, and reaction time are important cognitive variables in information processing that change in sleep deprivation. 35 Since using standard executive instructions requires individuals' cognitive functioning, therefore, changing the cognitive functioning of individuals at different hours of the day can affect the applicability of standard operating procedures.

Limitations

The limitations of this study included the small study interval, a large number of confounding variables, and the limit of generalizing the results to other organizations.

Conclusion

The results of this study indicated that the employees understood and considered the standard operating procedures positive lying and often considered the use of these procedures for better performance and reducing accidents. Also, from the viewpoint of employees, organizational factors (desirable organizational culture, continuous supervision and evaluation and assurance of accurate implementation of instructions, and continuous personnel training), individual factors (positive perception of personnel from the organization's goals, law obedience of personnel, and positive experiences of personnel from the implementation of instructions in the past), and environmental factors (environmental dynamics and their related SOP dynamics, desirable but law-based relationships of managers and supervisors with personnel as well as optimal and standard hours and shifts ) had a positive effect on the applicability of these procedures.

Conflicts of Interest

The authors declare that there is no conflict of interest.

Author contributions: All authors contributed equally to the study.

Acknowledgements

Authors would like to thank the employees of Tehran Oil Refinery who participated in this study.

References

- Jang N, Han K, Koo J, Yoon Y, Yong J, Yoon ES. Development of chemical accident classification codes and tool for management in process industries. Journal of chemical engineering of Japan. 2009;42:742-51.

- Amyotte PR, Berger S, Edwards DW, Gupta JP, Hendershot DC, Khan FI, Mannan MS, Willey RJ. Why major accidents are still occurring. Current opinion in chemical engineering. 2016 Nov 1;14:1-8.

- Macza M. A Canadian perspective of the history of process safety management legislation. Proceedings of the 8th Internationale Symposium Programmable Electronic System in Safety-Related Applications2008. p. 2-3.

- Gunasekera M, De Alwis A. Process industry accidents in Sri Lanka: Analysis and basic lessons learnt. Process Safety and Environmental Protection. 2008;86:421-6.

- Hofmann DA, Jacobs R, Landy F. WITHDRAWN: Reprint of “High Reliability Process Industries: Individual, Micro, and Macro Organizational Influences on Safety Performance”. Journal of Safety Research. 2013.

- Rosenthal I, Kleindorfer PR, Elliott MR. Predicting and confirming the effectiveness of systems for managing low‐probability chemical process risks. Process safety progress. 2006;25:135-55.

- Abidin MZ, Rusli R, Khan F, Shariff AM. Development of inherent safety benefits index to analyse the impact of inherent safety implementation. Process Safety and Environmental Protection. 2018 Jul 1;117:454-72.

- Kwon H-m. The effectiveness of process safety management (PSM) regulation for chemical industry in Korea. Journal of Loss Prevention in the Process Industries. 2006;19:13-6.

- Bullemer PT, Hajdukiewicz JR. A study of effective procedural practices in refining and chemical operations. Proceedings of the Human Factors and Ergonomics Society Annual Meeting: SAGE Publications Sage CA: Los Angeles, CA; 2004. p. 2401-5.

- Jamieson GA, Miller CA. Exploring the “culture of procedures”. Proceedings of the 5th International Conference on Human Interaction with Complex Systems: Urbana, IL Beckman Institute; 2000. p. 141-5.

- Sasangohar F, Peres SC, Williams JP, Smith A, Mannan MS. Investigating written procedures in process safety: Qualitative data analysis of interviews from high risk facilities. Process Safety and Environmental Protection. 2018;113:30-9.

- Krippendorff K. Content analysis: An introduction to its methodology: Sage publications; 2018.

- Schade J, Schlag B. Acceptability of urban transport pricing: Valtion Taloudellinen Tutkimuskeskus Helsinki, Finland; 2000.

- Arasteh H, Salimi M. Developing a model for leadership effectiveness in nursing colleges at Islamic Azad University. Quarterly Journal of Nursing Management. 2013;2:19-29.

- Heller R. Managing change: Dorling Kindersley Ltd; 2009.

- Cameron KS, Quinn RE. Diagnosing and changing organizational culture: Based on the competing values framework: John Wiley & Sons; 2011.

- Robbins SP, Coulter M. Principles of management. Translated by Seyyed Mohammad Arabi and Mohammed Ali Hamid Rafiee and Behrouz Asrari Ershad, Fourth Edition, Tehran: Office of Cultural Studies. 2007.

- Vosoughi S, Dana T, Serajzadeh N. Providing management system audit HSE-MS pattern for printing using ANP and DEMATEL model with emphasis on assessment methods of D & S and MISHA and OGP. Iran Occupational Health. 2015;

12:1-14.

- Yanj V, Lahijaniyan H. Systemhaye imeni. entesharate daneshgahe elmosanate iran. 1998.

- Cooper M, Phillips R, Sutherland V, Makin P. Reducing accidents using goal setting and feedback: A field study. Journal of occupational and organizational psychology. 1994;67:219-40.

- Kaafarani HM, Itani KM, Rosen AK, Zhao S, Hartmann CW, Gaba DM. How does patient safety culture in the operating room and post-anesthesia care unit compare to the rest of the hospital? The American Journal of Surgery. 2009;198:70-5.

- Nuri H. Comparison of safety culture in the two oil companies in 2008. J Tehran Uni Med Sci. 2008;71:84-9.

- Nasiri P, Alizade S, Ahmadlu M. Development of an effective safety culture. Publisher Islamic Azad University. Science and Research Branch. 2007:31-40.

- Ooshaksaraie M, Samudi Yasir M, Amran Ab M RY. Safety culture evaluation in the metal products industry of Iran. European Journal of Social Sciences. 2009;11:160-9.

- Wu T-C, Lin C-H, Shiau S-Y. Developing measures for assessing the causality of safety culture in a petrochemical industry. Water, Air, & Soil Pollution: Focus. 2009;9:507.

- Heydari M, Farshad A, Arghami S. The relationship between safety climate and safety behavior in the line of metal industry employees Arak. J Tehran Uni Med Sci. 2001;51:371-8.

- Allouch A, Koubâa A, Khalgui M, Abbes T. Qualitative and quantitative risk analysis and safety assessment of unmanned aerial vehicles missions over the internet. IEEE Access. 2019 Apr 23;7:53392-410.

- DeJoy DM, Della LJ, Vandenberg RJ, Wilson MG. Making work safer: Testing a model of social exchange and safety management. Journal of safety research. 2010 Apr 1;41(2):163-71.

- Cooke DL, Rohleder TR. Learning from incidents: from normal accidents to high reliability. System Dynamics Review. 2006;22:213-39.

- Shooks M, Johansson B, Andersson E, Lööw J. Safety and Health in European Mining: A report on safety and health, statistics, tools and laws, produced for the I2Mine (Innovative Technologies and Concepts for the Intelligent Deep Mine of the Future) project: Luleå tekniska universitet; 2014.

- Price JL. Reflections on the determinants of voluntary turnover. International Journal of manpower. 2001.

- Moghimi SM, Ramezan M. Organization and management research approach. Tehran. cashmere Publications; 2006.

- Labbafinejad Y, Attarchi MS, Azimzadeh B, Serajzadeh N, Namvar M. Comparison of sleep disorders in shift and non-shift workers employed in a printing factory in Tehran 2010. Razi Journal of Medical Sciences. 2013;19:1-8.

- Swenson DX, Waseleski D, Hartl R. Shift work and correctional officers: Effects and strategies for adjustment. Journal of Correctional Health Care. 2008;14:299-310.

- Golbabaei F, Dehghani F, Saatchi M, Zakerian SA. Evaluation of occupational exposure to different levels of mixed organic solvents and cognitive function in the painting unit of an automotive industry. Health promotion perspectives. 2018;8:296.

Type of Study: Research |

Subject:

General

Received: 2021/06/28 | Accepted: 2021/08/14 | Published: 2021/07/19

Received: 2021/06/28 | Accepted: 2021/08/14 | Published: 2021/07/19

Send email to the article author

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |